A boost to your pocket as well as your performance. Use code PRO25 for 10% off* genuine parts and supplies. Maximum discount per order £50. Visit the AGCO shop now.

Agricultural Engineers

A boost to your pocket as well as your performance. Use code PRO25 for 10% off* genuine parts and supplies. Maximum discount per order £50. Visit the AGCO shop now.

Come along, meet the team and view a range of our products.

John H McNae Ltd are pleased to announce that we are now selling Sumo cultivation and seeding farm machinery products. Sumo offers a farming system that puts soil at the centre of your farm universe. From Low Disturbance Subsoilers to Trio Combination Cultivators Sumo has the products to suit your cultivation needs.

For enquiries call 01292 541920 or Stewart Watt on 07506 554138.

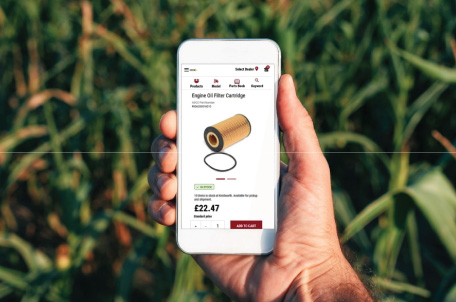

We’ve made ordering parts even easier as you can now order your parts online, simply visit the AGCO shop today and get browsing.

When it comes to replacement parts for your AGCO machine, the genuine choice is the only choice! AGCO Parts are made specifically for AGCO brands. We deliver the dependability you can rely on, with the productivity you’ve come to expect. When you see the AGCO Parts hologram, you know it’s the original equipment part, which will maximise performance and uptime and keep your machinery running the way it’s meant to.

Knowledge and experience are what it takes to farm your land productively. Understanding that every little part can make a big difference to your effectiveness.

Whether you are preparing ahead or out in the field, we’ll have what you need. You are the expert at farming your land and we are behind you with every step.

A perfect partnership. Bringing expertise to the field.

If it wasn’t for your wellies where would you be… we can help you out with our fantastic £10 deal of clearance stock wellies. Limited stock of green and black Nora wellies available. Call 01292541920 to reserve yours today. (Price shown excludes VAT)

Introducing Chrome cleaning products to John H. McNae Ltd, we have a wide selection of kits in stock. Pop into our shop or call 01292541920 to order yours today!